Artificial intelligence has completely redefined how many industries work, from real estate to software development. This innovative technology has the power to optimize and automate, which is why AI in manufacturing is more than just a hot trend. With 51% of European and 28% of US manufacturers using it, the technology has already rooted itself in the industry.

In this article, we will showcase the best ways to use AI for your production. Whether you want to cut costs or simply modernize your business, there is a way to do it with AI. That includes forecasting maintenance needs, automating assembly, and surveying inventory. But more on that below, with Uvik’s guide to AI in manufacturing industry.

5 Ways That AI is Changing the Manufacturing Industry

Let’s start by explaining exactly how artificial intelligence improves production. We’ll list the five core ways in which AI can reshape your manufacturing processes, explaining each one.

Predictive Maintenance

Predictive Maintenance

One of the inevitable issues during production comes when your equipment needs to be stopped for maintenance. It causes sudden downtime while incurring significant repair expenses. With AI forecasting, you can analyze data from your machines to predict maintenance. This lets you avoid extensive stoppages, as well as do more minor repairs, avoiding costlier work.

This is a typical use of AI in manufacturing, as it works as a cost saver and a way to analyze your operations. It helps determine if your current machines should potentially be replaced or could be used in a more optimal way to minimize wear.

Quality Control

Quality Control

Another widespread use case is the AI inspection of products. Through this method, you can find defective products faster and pinpoint the flaws with more precision. Using AI analysis, the production team can also determine what has caused the defect and eliminate the problem at the source. With AI used in manufacturing, the overall quality of your goods will go up.

Automated Production

Automated Production

With the help of human oversight, AI systems automate tasks like assembly, welding, and packing. This will not only speed up the processes but drastically lower the cost of production. As AI in manufacturing is learning rapidly, more and more points in the manufacturing process will be available for automation.

Supply Chain Management

Supply Chain Management

As their business grows, manufacturers need to adapt their inventory levels and analyze the market to get ahead of demand. By using AI, companies can forecast the changes in demand and adapt their inventory accordingly. Similarly, using complex algorithms, you can calculate the best transportation routes.

With these improvements, you can cut down the delivery time, as well as anticipate rises in demand. It helps manufacturers know the market better and be more efficient. This use of AI in manufacturing industry will simply help you be a stronger business, as you’ll see the direction of the market before your competitors do.

Product Development

Product Development

Speaking of being in the know about the market, AI can also analyze customer behavior and upcoming trends. This will give you time to prepare new product ideas, helped by designs and prototypes created by AI. Using generative models, a manufacturer can quickly draw up their future line of products.

What are the Benefits of AI in Manufacturing?

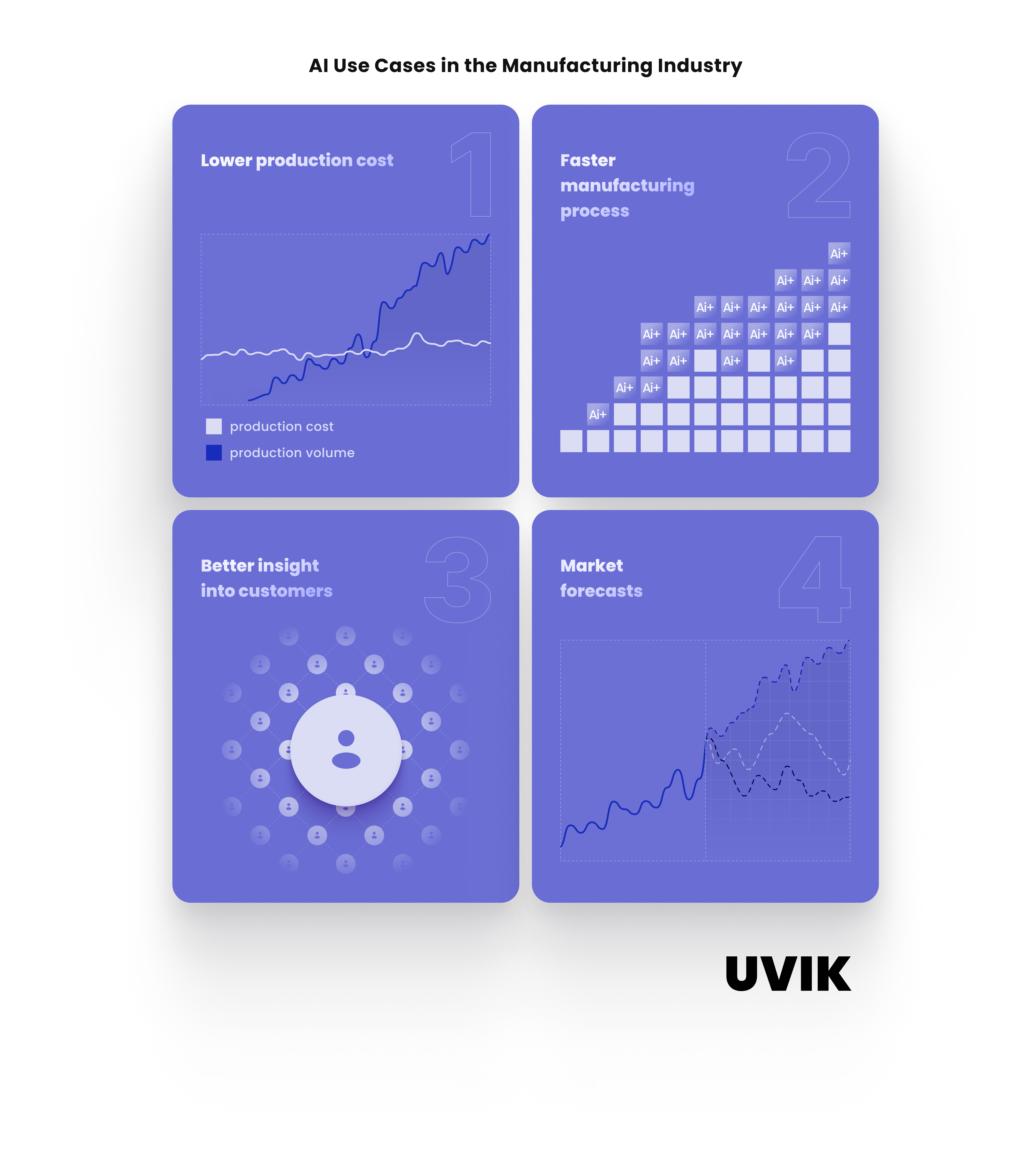

We’ve shown that AI can affect pretty much any part of your business. From the very first product design stages to the delivery to customers, there are ways to use it. Thanks to this versatility, AI has the following benefits:

- Lower production cost

- Faster manufacturing process

- Better insight into customers

- Market forecasts.

Depending on which parts of the business you apply AI to, you could reap all of these advantages. While the technology is still growing and changing, it’s already showing its potential to completely transform industries in a variety of cases. The use of AI in manufacturing will surely keep expanding, so there’s value in jumping on board now.

Depending on which parts of the business you apply AI to, you could reap all of these advantages. While the technology is still growing and changing, it’s already showing its potential to completely transform industries in a variety of cases. The use of AI in manufacturing will surely keep expanding, so there’s value in jumping on board now.

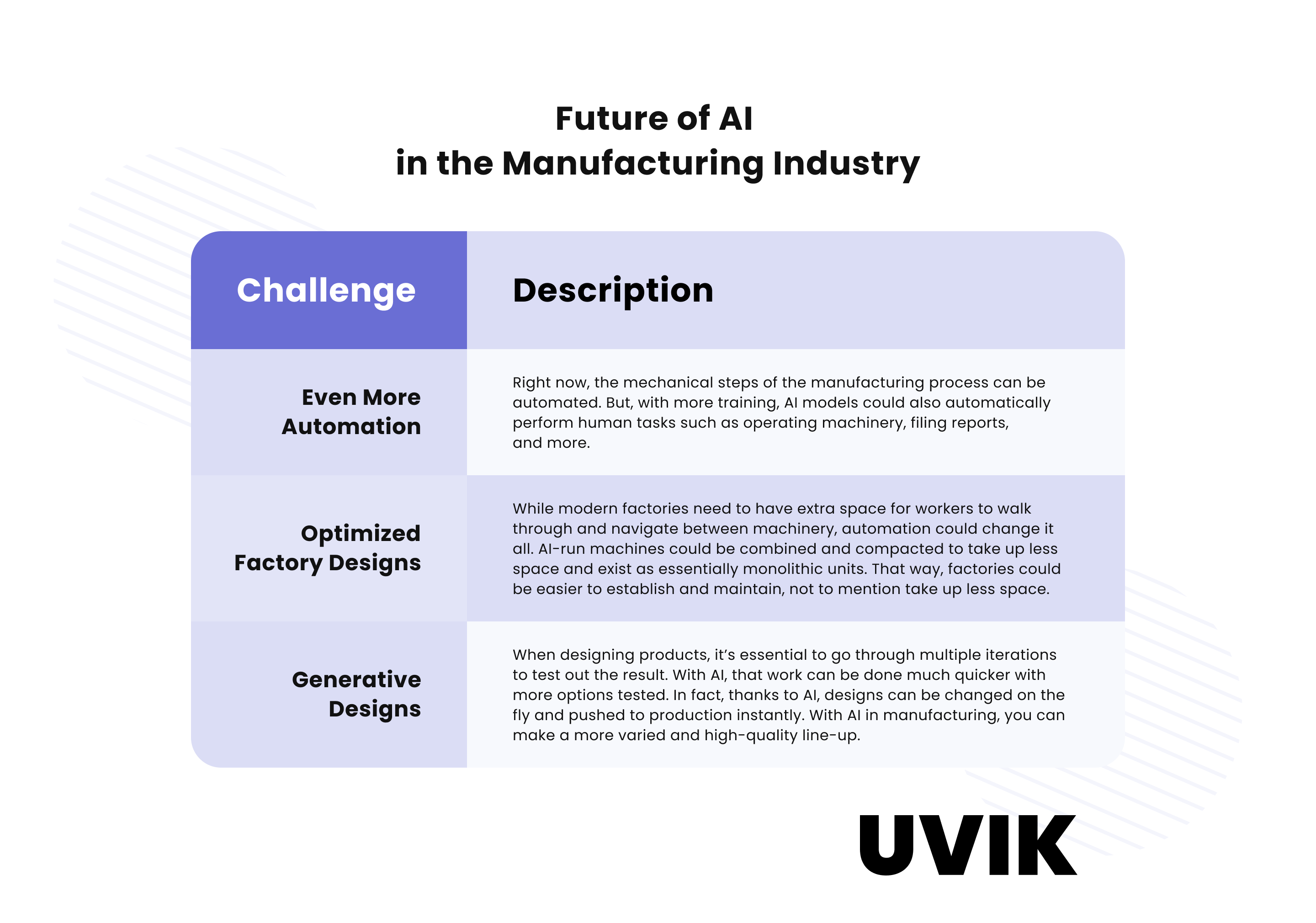

What is the Future of AI in the Manufacturing Industry?

While AI today is already impressive, the future of AI in manufacturing could be even more transformative. Let’s quickly list a few examples of what it could do.

Even More Automation

Right now, the mechanical steps of the manufacturing process can be automated. But, with more training, AI models could also automatically perform human tasks such as operating machinery, filing reports, and more.

Optimized Factory Designs

While modern factories need to have extra space for workers to walk through and navigate between machinery, automation could change it all. AI-run machines could be combined and compacted to take up less space and exist as essentially monolithic units. That way, factories could be easier to establish and maintain, not to mention take up less space.

Generative Designs

When designing products, it’s essential to go through multiple iterations to test out the result. With AI, that work can be done much quicker with more options tested. In fact, thanks to AI, designs can be changed on the fly and pushed to production instantly. With AI in manufacturing, you can make a more varied and high-quality line-up.

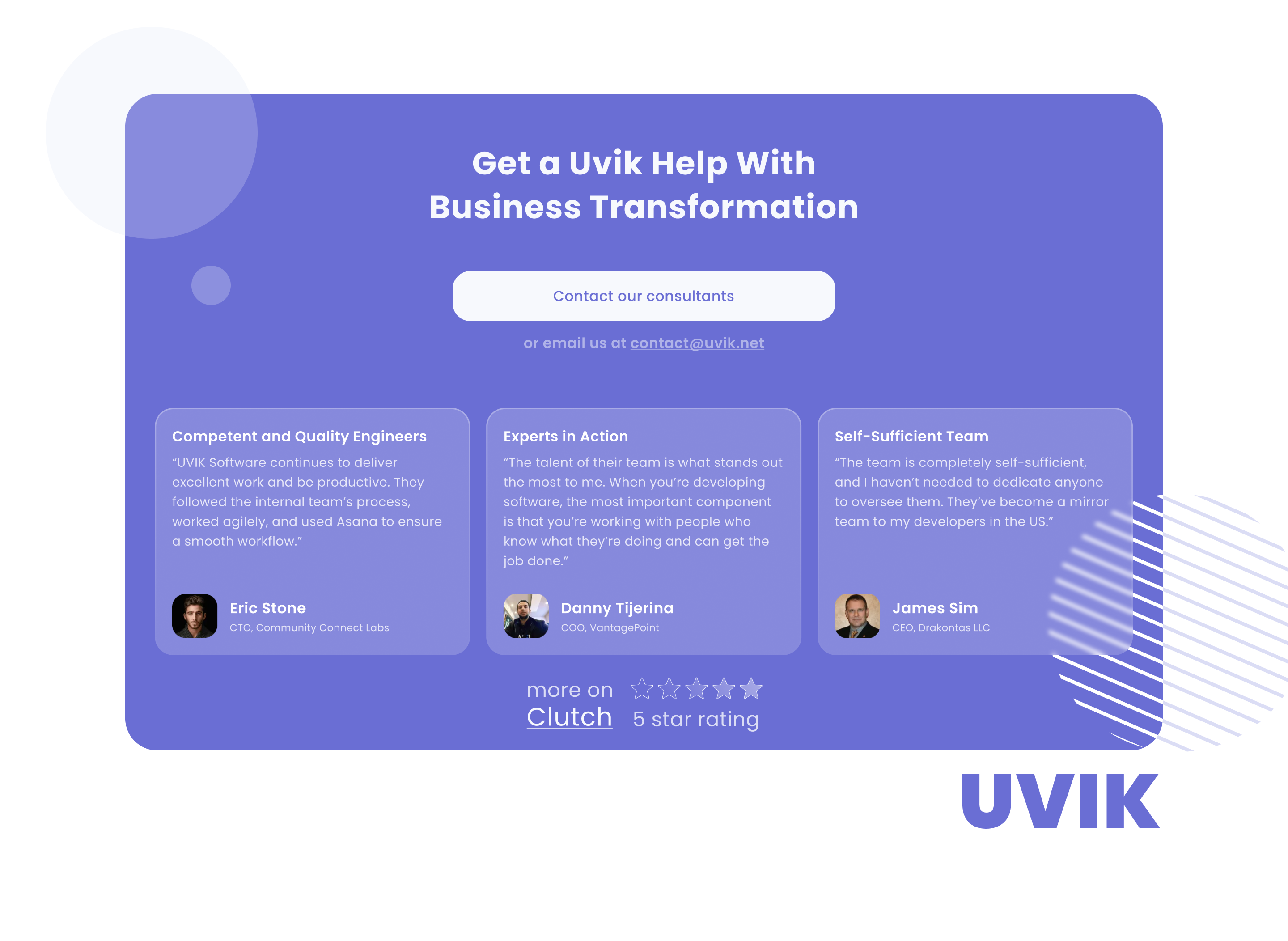

How Can Uvik Help With Business Transformation?

As you can see, there are many benefits of AI in manufacturing. It can help your business save money, increase product quality, and get an edge over the competition. With these advantages, you’re probably eager to start this new chapter in your company’s history. After all, AI will only get better, and taking advantage of it is the smart move.

Of course, such a powerful technology needs proper implementation to make the most of its features. For that, you need a reliable partner that can guide your transformation. This is where Uvik comes in – a modern team of professionals. With eight years of experience as a company and decades in the industry for our specialists, we know the tech deeper than anyone.

If you want to see what artificial intelligence manufacturing can achieve, contact us now. We’ll provide a consultation to help you understand how to use AI in your company. Once you’ve decided what features you want, we can turn your manufacturing business into a forward-thinking AI-powered company. Get in touch to get started.

FAQ

How is AI implemented in manufacturing?

How do you implement AI solutions in manufacturing?

What are the challenges of AI in manufacturing?

How to reduce the costs of AI implementation for a manufacturing company?